Winter and Concrete: Preventing Freeze-Thaw Damage

Understanding the Phenomenon of Freeze-Thaw Damage

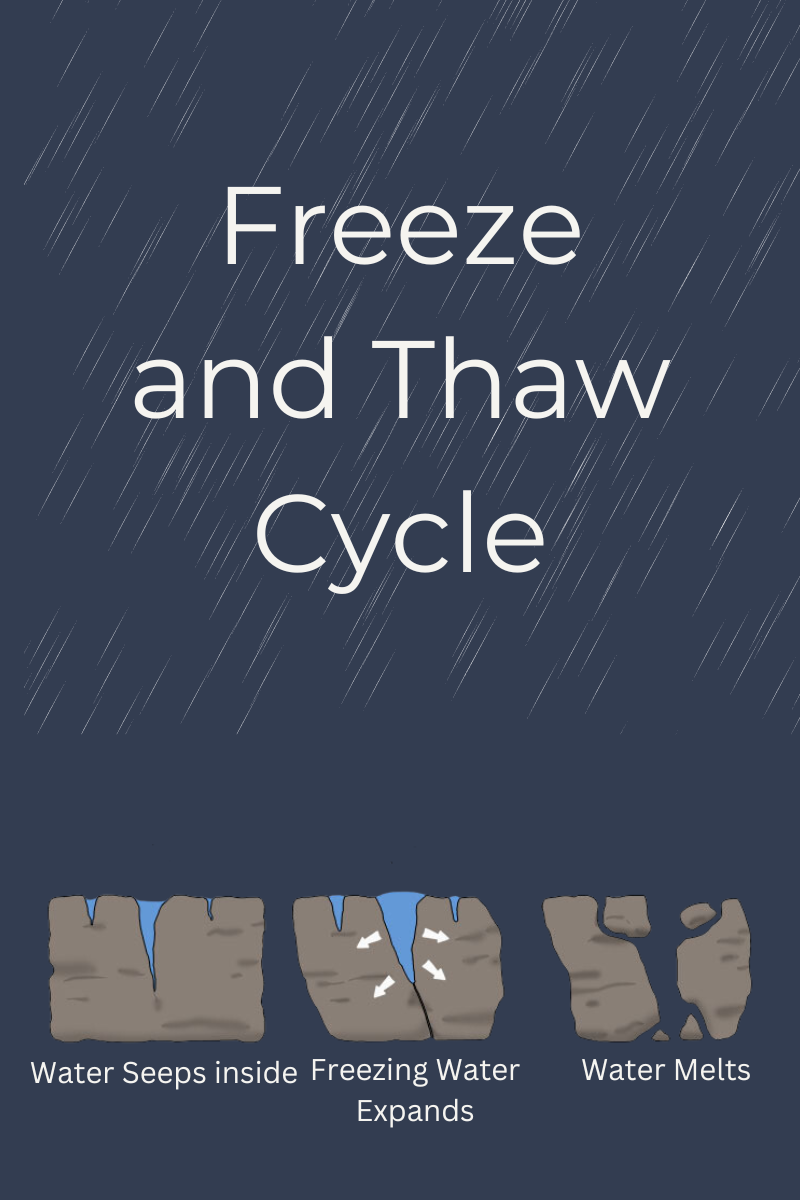

Freeze-thaw damage is one of the most critical problems faced by concrete structures, especially during the cold winter months. This phenomenon happens when water infiltrates the concrete's pores and freezes. As water freezes, it expands, exerting pressure on the concrete's interior. When the ice melts, the pressure reduces, only to be reinstated during the next freezing cycle. Over time, this relentless cycle leads to cracks, fissures, and ultimately, structural failure.

Why Concrete is Vulnerable in Winter

Concrete is inherently porous. While it may seem solid and unyielding, it contains minute spaces that absorb moisture from its surroundings. During winter, water can easily seep into these pores. When temperatures plummet, the entrapped water becomes ice, expanding in volume by nearly 9%. This exerts immense internal stress on the concrete, resulting in visible cracks and damage.

Best Practices to Minimize Freeze-Thaw Damage

To ensure the longevity of concrete structures during harsh winters, we must adopt specific best practices that can counteract the detrimental effects of freeze-thaw cycles.

- Use of Air-Entrained Concrete: One of the most effective ways to combat freeze-thaw damage is by using air-entrained concrete. By deliberately introducing microscopic air bubbles into the mix, we provide space for freezing water to expand, thus reducing internal pressure.

- Apply a Quality Sealer: Properly sealing the concrete surface can significantly reduce water penetration. We recommend using a penetrating sealer for enhanced protection against moisture.

- Ensure Proper Drainage: Ensuring that water does not pool on the concrete surface is crucial. We must establish adequate drainage solutions, such as sloping surfaces and installing drains, to prevent water accumulation.

- Prompt Removal of Ice and Snow: Allowing snow to accumulate on concrete surfaces can exacerbate freeze-thaw cycles. We should prioritize snow and ice removal to keep surfaces dry.

- Limit the Use of Deicing Salts: While salts can effectively melt ice, they can also accelerate concrete deterioration. We should opt for alternatives or use them judiciously.

Monitoring and Maintenance: A Proactive Approach

Even with the best preventive measures, we cannot entirely eliminate the risk of freeze-thaw damage. Therefore, we must adopt a proactive stance towards monitoring and maintenance. Regularly inspecting concrete surfaces for signs of wear, fissures, or discoloration can provide early indications of potential problems. Addressing these issues promptly can prevent minor concerns from escalating into significant structural problems.

Rapid Repair Solutions for Damaged Concrete

In situations where damage has already occurred, we have a range of rapid repair solutions to restore structural integrity.

- Epoxy Injection: This is ideal for sealing and binding cracks. By injecting epoxy resin into fissures, we create a bond that's often stronger than the original concrete.

- Overlay Systems: If the surface layer is extensively damaged, we can use overlay systems. These provide a new, resilient layer over the existing concrete, extending its lifespan.

- Concrete Replacement: In extreme cases, where damage is widespread and deep, the best course of action may be to replace entire sections of concrete. This ensures safety and longevity.

Conclusion: Building Resilience Against Winter's Wrath

Winter presents a formidable challenge to concrete structures. However, with the right understanding, preventive measures, and proactive maintenance, we can effectively shield our structures from freeze-thaw damage. By prioritizing the health and longevity of our concrete infrastructures, we not only ensure their lasting durability but also promote safety and resilience against the relentless cycles of nature.

Are Ready To Work With HAMILTON CONCRETE WORKS?

Let's get in touch!

Send us a message and we’ll be in touch.

Or give us a call today at 289-204-1632