Concrete Driveway

We are your trusted partner for concrete driveway services in the Hamilton area. With years of experience and a commitment to excellence, we specialize in providing comprehensive solutions for all your driveway needs. Whether you require a new driveway installation, repairs, resurfacing, or decorative options, our skilled team is here to deliver outstanding results that enhance the beauty and functionality of your property.

Instant Quote

Find out More About Your New Concrete Driveway in Hamilton

Driveway Repair Solutions You Can Trust

Does your driveway show signs of wear, like cracks, potholes, or surface imperfections? Trust in our experienced team to diagnose and deliver efficient repair solutions. We do crack sealing, patching, to comprehensive resurfacing.

Driveway Maintenance & Sealing

To maximize your driveway's lifespan, we offer robust maintenance and driveway sealing solutions. From surface cleaning to minor repairs, our team ensures your driveway is in prime condition. We apply a premium sealant, tailored to your driveway’s specific needs, protecting it against weather, UV damage, and daily wear. Whether it's acrylic, epoxy, penetrating, or polyurethane sealers, we recommend what's best.

Commitment to Excellence & Customer Satisfaction

Your satisfaction is our topmost priority. Reach out to Hamilton Concrete Works for a free consultation and quote. Experience the distinct advantage of partnering with a leading concrete contractor committed to unmatched quality and service.

Why to Install a Concrete Driveway

Opting for a concrete driveway is both a practical and aesthetic choice for any property owner. Here's why:

- Concrete driveways are a long-lasting investment, celebrated for their robustness that can endure for decades. The material's versatility means that it's not limited to the standard gray. Instead, it can be tailored to various finishes, seamlessly integrating with the surrounding architecture.

- Concrete offers tangible advantages. Its light-colored surface improves nighttime visibility, and specific finishes provide enhanced traction, ensuring safety for both pedestrians and vehicles. For those concerned about environmental impact, concrete driveways leave a smaller carbon footprint, blending sustainability with durability.

- Maintenance concerns are minimal with concrete. Apart from occasional upkeep and sealing, they withstand diverse weather conditions, from scorching sun to heavy rainfall. Their resistance to common driveway nuisances, like oil and petrol spills, ensures longevity with less wear and tear.

- In the broader perspective of property valuation, a well-laid concrete driveway suggests meticulous care and can enhance market value. It's not merely a path to your home but a reflection of the thought and investment you've poured into your property.

Our Concrete Driveway Installation Process

-

Planning and Design

The first step in installing a concrete driveway is the planning phase. We will determine the exact size and shape of your driveway, taking into account factors like the natural slope of your land, optimal water drainage, and easy access to your property.

-

Excavation

Once our plan is in place, the excavation process begins. This involves digging out the designated driveway area to the required depth, which is typically around 10-12 inches. It's crucial to remove any organic material, such as roots and loose soil, to ensure a stable foundation for your driveway.

-

Subgrade Preparation

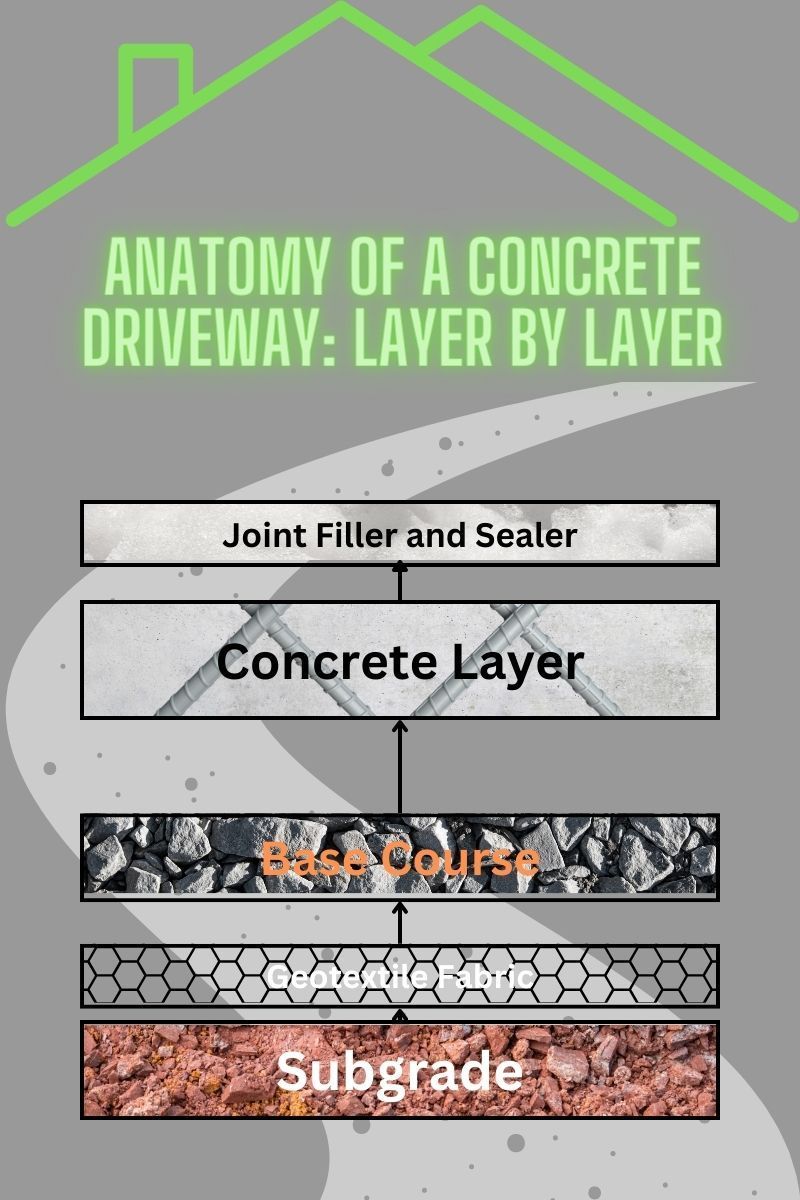

The subgrade, which is essentially the native soil where the driveway is being installed, must be compacted and leveled. It's of utmost importance that this layer is free from organic material to prevent unwanted shifts or settlements in the future. We will use a mechanical copactor and ensure that there is a minimum slope of 1% to 2% to ensure proper drainage.

-

Geotextile Fabric Installation

In regions with softer soils, a geotextile fabric might be necessary. This fabric stabilizes the soil and acts as a barrier, preventing the mixing of the subgrade with the aggregate base layer that we will be adding later.

-

Base Course Installation

After laying down the geotextile fabric, the next step is to pour in a layer of crushed stone or gravel, usually ranging from 4 to 8 inches in depth. This aggregate is then compacted to form a solid, stable base that ensures both stability and proper drainage for the driveway.

-

Formwork Setting

With the base course in place, it's time to set up the formwork. We will be using wooden boards or metal forms to outline and shape the driveway. We will securely anchored to hold the wet concrete that will be poured into them.

-

Reinforcement Addition

To ensure the longevity and durability of the concrete driveway, reinforcements such as steel reinforcing bars (rebar) or wire mesh are often added. These reinforcements help evenly distribute the weight on the driveway and can significantly reduce the risk of cracking over time to increase the longevity of the driveway.

-

Concrete Pouring

With everything set up, the concrete mixture, made of water, cement, sand, and aggregate, is prepared and poured into the formwork. Proper and even distribution is essential to prevent weak spots and ensure a uniform appearance.

-

Surface Finishing

Once the concrete has been poured, it needs to be smoothed out using trowels. At this juncture, homeowners can also opt for decorative finishes, such as stamping, brooming, printed and stenciled overlays, and JewelStone to add a touch of elegance to the driveway's appearance.

-

Control Joints Addition

Concrete naturally contracts and expands with temperature changes, expecially with Canadian extreme cold and warm thaw cycles. To guide where this movement occurs, control joints are cut into the concrete at regular intervals, usually every 10-15 feet. This strategic placement ensures that any cracks that form will do so predictably along these joints.

-

Curing Process

After the concrete has been laid and shaped, it needs to be cured for several days. Curing is a critical step, as it ensures the concrete reaches its potential strength. During this period, the surface should be kept moist to prevent premature drying, which could lead to surface cracking.

-

Sealing the Driveway

The final step is to protect the driveway with a quality sealer. Sealers shield the concrete from stains, adverse weather conditions, general wear and tear, and harsh UV rays thereby enhancing its lifespan and maintaining its appearance.

Concrete Driveway Finishes

Stamped Concrete

- cost-effective option for adding texture and flair to your driveway.

- Installation range from $90 to $140/m^2

- The textured finish adds design elements and provides improved traction for walking and driving.

- Regular rinsing or occasional low-pressure power washing may be required to keep the grooves free from dirt.

- Concrete color oxides can be added for a desired color finish.

Pavecut Concrete Service

- Pave cut finish offers homeowners the appearance of slate or pavers for their driveway.

- Can be combined with colored or brushed finishes for a modern style resembling natural slate.

- Size and pattern of the pave cut can be customized for a unique and personalized design.

- The pave cut lines are made using a diamond saw once the driveway has fully cured.

Exposed Aggregate Concrete

- Exposed aggregate offers a wide variety of texture options for driveways.

- An additive is mixed into the concrete to create a three-dimensional look with small stones, shells, or pebbles.

- The aggregate comes in various sizes and colors, allowing for a unique and customized appearance.

- Cost of an exposed aggregate concrete driveway ranges from $100 to $150/m^2,

- The final result is a textured, decorative, slip-resistant, and long-lasting driveway that can endure for many decades.

Plain Concrete

- Professionally poured and set concrete provides a clean and fresh look for driveways.

- Plain concrete is a popular choice due to its quick installation and cost-effectiveness.

- Cost for a plain concrete driveway typically ranges from $60 to $80/m^2

- Requires minimal maintenance and care to keep it in good condition.

- Proper sealing by a professional concrete service can extend its lifespan to at least 30 years.

Most dirt and grime can be easily washed away with a simple garden hose.

Coloured Concrete

- Professionally poured and set concrete offers a clean and fresh appearance for driveways.

- Plain concrete is a popular option due to its fast installation and cost-effectiveness.

- The cost of a plain concrete driveway typically falls within the range of $60 to $80,m^2

- It requires minimal maintenance and upkeep to keep it in good condition.

- Most dirt and grime can be effortlessly washed away using a garden hose.

Brushed Concrete

- Brushed or Stipple Finish is an economical option for adding texture and flair to your driveway.

- The installation cost for this finish type typically ranges from $90 to $140/m^2

- Professionals start by pouring a plain driveway, ensuring it is level and smooth.

- They then use specialized tools to create a brushed or scalloped look on the surface, employing various brush strokes and trowel patterns.

- It's important to note that the concrete grooves created by the brushing effect may hold onto dirt more, requiring regular rinsing or occasional power washing at a lower psi to maintain its appearance.

-

How often should I seal my concrete driveway?

It is recommended to seal your concrete driveway every 2-3 years to maintain its appearance and protect it from weathering and stains.

-

How long does it take to install a new concrete driveway?

The installation time for a concrete driveway can vary depending on factors such as the size of the driveway, site preparation requirements, and weather conditions. On average, it takes around 3-7 days from excavation to the completion of a standard-sized driveway.

-

How do I maintain my concrete driveway?

To maintain your concrete driveway's longevity and appearance, it is recommended to keep it clean by regularly sweeping away debris and washing it with a mild detergent. Avoid using harsh chemicals or de-icing agents that can damage the concrete. Additionally, promptly repair any cracks or damage and consider periodic resealing to protect the surface from stains and weathering.

Want to Transform Your Space With a New Concrete Driveway in Hamilton, Ontario?

Our team of professionals is ready to speak with you and improve your space today! Don't hesitate and give us a call!

We serve Hamilton and the surrounding communities with our utmost dedication to your satisfaction. Locally owned and operated for more than 20 years, our mission is to be your go-to concrete service provider in known for reliability, craftsmanship, and commitment to excellence.

Please visit our friends at

Epoxy flooring Hobart

Company

Business Hours

Business Hours

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Appointment Only

- Sunday

- Appointment Only

Contact Information

Business Address: 1241 King Street West, Hamilton ON L8S 1M5

Phone Number: 289-204-1632

Email Address: hamiltonsconcrete@gmail.com

@ 2024 All Rights Reserved | Hamilton Concrete Works | Made by Visionary Leads