Uncovering Common Misconceptions about Concrete Service

| Section | Key Points |

|---|---|

| Versatility of Concrete Service | Decorative concrete, stamped and colored options, aesthetic versatility. |

| Understanding the Concrete Mix | Different mixes for different projects, importance of understanding the science behind concrete mixtures. |

| Types of Concrete Mixes | Normal Strength, High-Strength, High-Performance, Air Entrained Concrete, each with unique properties and applications. |

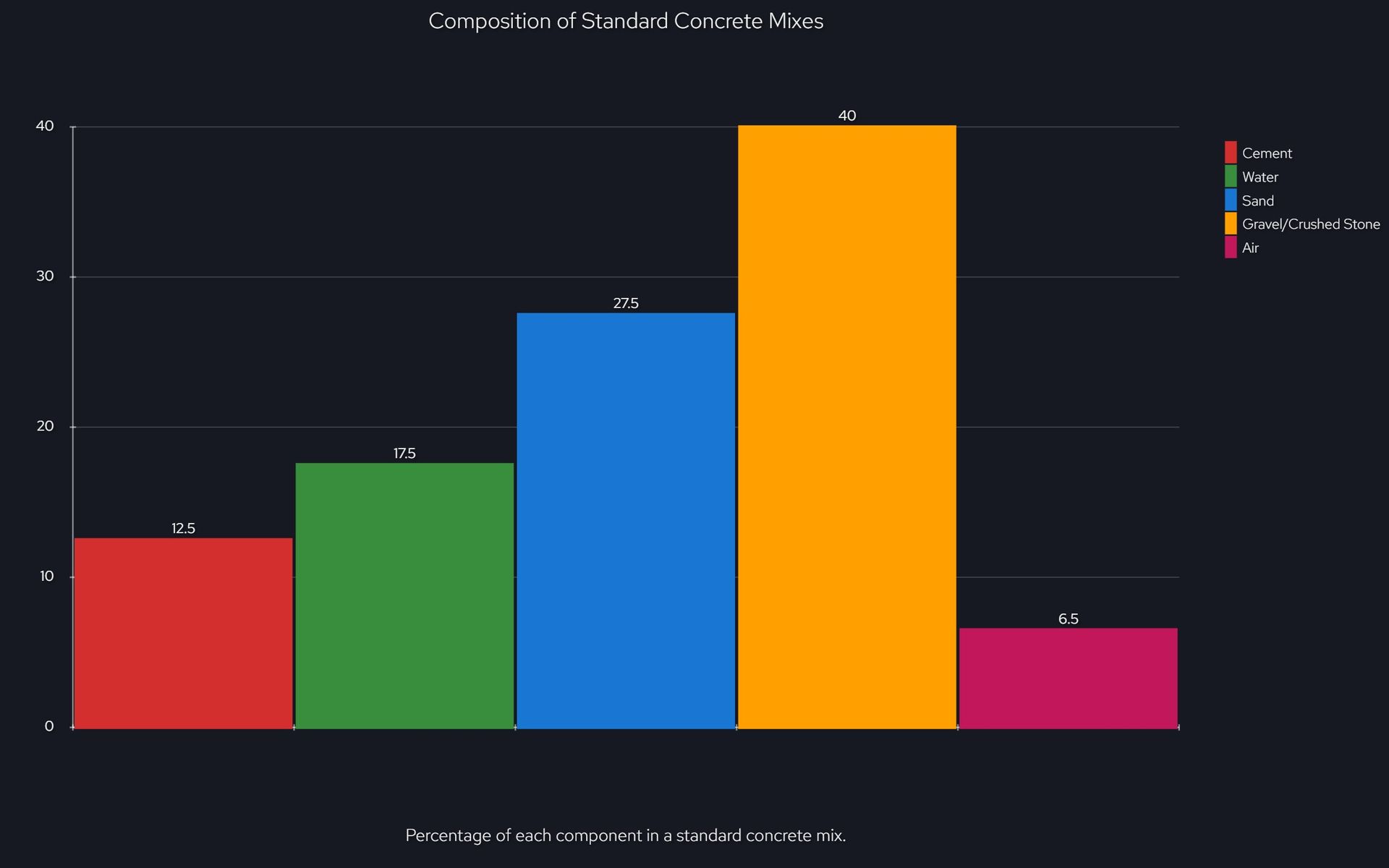

| Composition of Standard Concrete Mixes | Cement (10-15%), Water (15-20%), Fine Aggregate - Sand (25-30%), Coarse Aggregate - Gravel or Crushed Stone (30-50%), Air (5-8%). |

| Concrete is Not Indestructible | Needs proper care and maintenance, regular cleaning, sealing, crack repair, avoiding deicers. |

| Eco-friendly Nature of Concrete | Sustainable, made from abundant natural resources, recyclable. |

| Concrete and Cold Weather | Can be installed in cold weather with precautions. |

| Cost of Concrete Service | Not prohibitively expensive, cost-effective in the long run. |

| Final Thoughts | Emphasizes the importance of understanding concrete services, its benefits, and versatility. Highlights the promising future of the concrete service industry. Encourages high-quality concrete service for durable structures. |

In the world of construction and landscaping, concrete service remains a cornerstone of the industry, yet it is still shrouded with a myriad of misconceptions. In this comprehensive guide, we aim to debunk these fallacies, providing a clear, objective perspective on the benefits and versatility of concrete service.

The Versatility of Concrete Service

Contrary to popular belief, concrete isn't merely a 'grey and boring' material. With the rise of decorative concrete, the material's design capabilities have significantly broadened. From stamped concrete that mimics natural stone, to colored concrete that adds an artistic touch, it's high time we appreciate the aesthetic versatility concrete service offers.

Understanding the Concrete Mix

Another common fallacy is that all concrete is the same. However, the truth is, the strength and durability of concrete depends significantly on the mix. Different projects necessitate different concrete mixes. By comprehending the science behind concrete mixtures, professionals can create a blend that ensures maximum performance and longevity.

Diving Deeper: Different Types of Concrete Mixes

Understanding the different types of concrete mixes is essential to harness the full potential of this versatile material. Concrete mix selection is primarily dictated by the project's requirements. Let's explore some common types:

Normal Strength Concrete

This is the most frequently used type of concrete mix for regular construction projects. It possesses a compressive strength between 20 MPa to 50 MPa and is typically composed of sand, cement, aggregate, and water. It's an economical choice but may not be ideal for heavy-duty applications.

High-Strength Concrete

For more demanding projects, high-strength concrete, with a compressive strength exceeding 60 MPa, is used. Special materials like silica fume or high-range water reducers are often added to achieve this high strength. The primary advantage is its extraordinary strength, but the tradeoff is a higher cost.

High-Performance Concrete

High-performance concrete is designed to ensure ease of placement, long-term mechanical properties, toughness, volume stability, and enhanced aesthetic characteristics. The focus is more on performance over strength. It's versatile but can be challenging to prepare due to its specific requirements.

Air Entrained Concrete

Air entrained concrete contains tiny air bubbles that improve its resistance to freeze-thaw cycles, making it an excellent choice for colder climates. The downside is that these air pockets can reduce the overall strength of the concrete.

A concrete mix comprises several components, each contributing unique properties. Let's delve deeper into the composition of standard concrete mixes:

Cement (10-15%)

Cement acts as the binding agent in concrete, allowing the mixture to harden and maintain its shape. It usually makes up about 10-15% of the total volume of the concrete mix.

Water (15-20%)

Water is critical in activating the cement and facilitating the hardening process through hydration. It typically comprises about 15-20% of the total mix. However, the precise amount depends on the water-cement ratio, a crucial factor determining the concrete's strength and durability.

Fine Aggregate - Sand (25-30%)

Fine aggregate, commonly sand, fills the gaps between the cement particles and coarse aggregate. It generally constitutes about 25-30% of the mix. It provides volume, stability, and resistance to wear and erosion.

Coarse Aggregate - Gravel or Crushed Stone (30-50%)

The coarse aggregate, usually gravel or crushed stone, forms the bulk of the concrete mix, making up 30-50% of the total volume. It gives concrete its strength and greatly influences its durability and thermal properties.

Air (5-8%)

A percentage of the concrete mix (approximately 5-8%) is intentionally left as air. The incorporation of tiny, discrete air pockets enhances the concrete's resistance to freeze-thaw cycles, improving durability in cold climates.

The above percentages give a rough guide and can vary depending on the specific requirements of the project. The choice and proportions of these constituents define the concrete's performance characteristics such as strength, durability, workability, and finish.

Concrete is Not Indestructible

While it's true that concrete is robust and durable, it isn't invincible. Proper care and maintenance are crucial to prevent cracks, scaling, and other forms of wear and tear. Regular sealing and cleaning can greatly enhance the lifespan of your concrete structures.

Regular Cleaning

Use a mild detergent and water to remove stains and dirt from the concrete surface. Pressure washing can be used for tougher stains, but care must be taken not to damage the concrete.

Sealing

Sealing your concrete helps to protect it from water, chemicals, and UV rays. High-quality sealants can also enhance the color and sheen of decorative concrete. It's generally recommended to reseal exterior concrete every 2-3 years.

Crack Repair

Even with the best care, concrete can develop cracks over time. Small cracks can be filled using a concrete patching compound. For larger cracks, a professional concrete repair service should be sought to ensure the structural integrity isn't compromised.

Avoiding Deicers

During winter, avoid using deicers on concrete as they can cause surface damage. Sand can be used for traction without harming the concrete.

The Eco-friendly Nature of Concrete

The belief that concrete service is harmful to the environment is another fallacy. In fact, concrete is one of the most sustainable materials in the construction industry. It's made from abundant, natural resources and its long lifespan reduces the need for replacement. Moreover, concrete is recyclable, thus contributing to the circular economy.

Concrete and Cold Weather

The notion that concrete cannot be installed during cold weather is a misconception. Concrete can be placed in colder temperatures, albeit with certain precautions. The use of insulated blankets, heated enclosures, and accelerators ensure the curing process proceeds normally.

The Cost of Concrete Service

The presumption that concrete service is prohibitively expensive is yet another misconception. When considering the material's lifespan, minimal maintenance, and adaptability, the investment in concrete service often proves cost-effective in the long run.

Final Thoughts

Misconceptions often stem from lack of knowledge or misinformation. By learning more about concrete services, its benefits, and versatility, we can dispel these misconceptions and fully appreciate this humble, yet essential, construction material.

Through continuous research and technological advancements, the future of concrete service looks promising. By debunking these common misconceptions, we can look forward to a better understanding and further enhancement of the concrete service industry.

Remember: High-quality concrete service not only elevates the aesthetic appeal of your project but also ensures a solid, durable structure that stands the test of time.

Are Ready To Work With HAMILTON CONCRETE WORKS?

Let's get in touch!

Send us a message and we’ll be in touch.

Or give us a call today at 289-204-1632

We will get back to you as soon as possible.

Please try again later.

We serve Hamilton and the surrounding communities with our utmost dedication to your satisfaction. Locally owned and operated for more than 20 years, our mission is to be your go-to concrete service provider in known for reliability, craftsmanship, and commitment to excellence.

Please visit our friends at

Epoxy flooring Hobart

Company

Business Hours

Business Hours

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Appointment Only

- Sunday

- Appointment Only

Contact Information

Business Address: 1241 King Street West, Hamilton ON L8S 1M5

Phone Number: 289-204-1632

Email Address: hamiltonsconcrete@gmail.com

@ 2024 All Rights Reserved | Hamilton Concrete Works | Made by Visionary Leads